"kanadanmajava1" (kanadanmajava1)

"kanadanmajava1" (kanadanmajava1)

10/26/2016 at 10:38 ē Filed to: None

0

0

4

4

"kanadanmajava1" (kanadanmajava1)

"kanadanmajava1" (kanadanmajava1)

10/26/2016 at 10:38 ē Filed to: None |  0 0

|  4 4 |

Iím planning to buy an used Auto Verdi (dry sump) oil pump for my Opel BTCC replica project. Why Auto Verdi? Because their pumps are very good and Swedish made. Getting spare parts or sending the whole pump for maintenance is easier if the manufacturer is in neighboring country.

But they have one downside (besides the high price). Most of their models use very weird fittings for the oil lines. The weird fittings arenít just limited to Auto Verdi pumps but they seem to have these very often.

The high pressure side uses -10AN or -12AN in nearly all cases but the other ports have some variety of these:

-AN12-AN16 (no problems with these)

-Wiggins fittings (unknown size but not very problematic)

-small 4-bolt flange (rectangular)

-large 4-bolt flange (~square)

-2-bolt flange

-ORB with 1

1

/

8

-20 UN thread

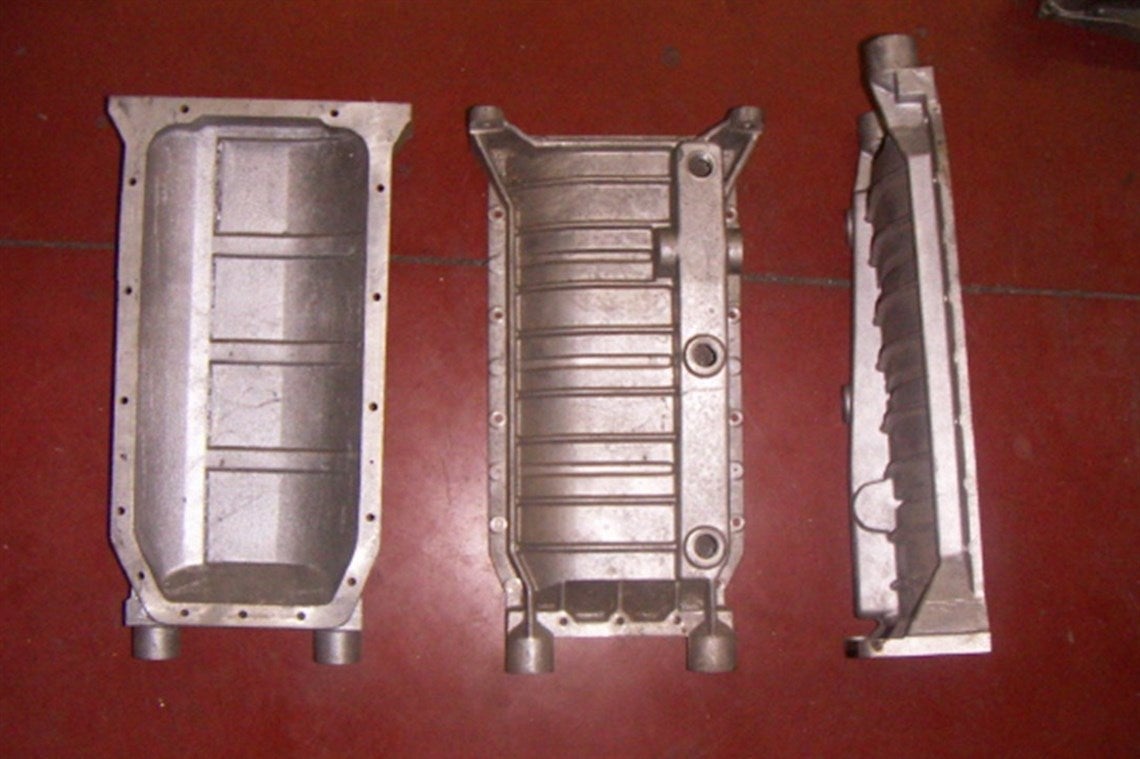

Iím pretty sure that the 2-bolt flange fitting is compatible with either of the 4-bolt flanges but this is just my assumption. In the picture above the AN fitting, the both variations of 4-bolt flange and weird ORB fittings can be seen.

If someone has some knowledge about the specialty fittings used in modern dry sump pumps I would be pleased to hear some hints. The compatibility of various 4-bolt and 2-bolt fittings is my main question in this case.

I could of course solve my problem by buying a pump with all lines in place. Then I could chop up the old lines and re-crimp them with suitable fittings and hoses. But most sellers sell the pumps as they are and I cannot see if the pump internals are doing fine if the lines are installed. And the full set of used lines will push the price up quite a lot too.

Auto Verdi has BMRS as their official fittings provider and they do have all of the required fittings. But Iím afraid that a full set of brand new fittings from them would be really expensive. I didnít find any prices for them but they do look very nice and expensive. Here are some examples for the†fitting types that Iím looking for:

†

uofime-2

> kanadanmajava1

uofime-2

> kanadanmajava1

10/26/2016 at 14:12 |

|

Where are the fittings with the bolted flanges going?

Are they going to the pump on used on the motor/oil pan, they may not even be of concern to you.

Do you have an oil pan picked out as well?

They look like theyíre just going to an AN hose with a crimp so you can maybe find somewhat more universal adapters then use AN fittings to do whatever bends/transitions are necessary.

kanadanmajava1

> uofime-2

kanadanmajava1

> uofime-2

10/26/2016 at 16:46 |

|

Those flanged fittings are the return lines to the oil tank. For some reason in most Auto Verdi pumps the lines coming from the sump pan are routed (through the ORB fittings) to the pump (middle stages) and they are joined together as one return line. The last pump stage is a return line from some other location (lifter valley) and itís routed with a separate line to the tank. The first stage is the oil inlet line to the engine and in some pumps it has an internal pressure regulator.

Iím pretty sure that I have to modify an existing pan. There are some dry sump pans for the C20XE but most use only two scavenge stages. This used one by unknown manufacturer looks to be the most promising.

Iím still thinking about making the sump pan from a factory steel oil pan. Then I could place the scavenging outlets freely.

uofime-2

> kanadanmajava1

uofime-2

> kanadanmajava1

10/27/2016 at 10:13 |

|

Thatís good news because thereís no reason you can have more standard parts put on your reservoir, for that matter they sell off the shelf reservoirs that just use regular fittings so its really easy to entirely avoid that issue.

Thereís two big reasons to use a dry sump system, one is the remote reservoir helps guarantee pressure in sustained high G situations the other is that you can run a super shallow pan allowing your to mount your engine a few inches lower in the chassis and generally improving packaging as well as nearly eliminating crank slap and aeration from that.

kanadanmajava1

> uofime-2

kanadanmajava1

> uofime-2

10/27/2016 at 17:44 |

|

Thereís also a third good reason. If you manage to use high vacuum scavenging stages it will also help to get piston rings work better. They seal better with less surface tension. Though this requires changing the pistons rings to ones that have suitable ďpreloadĒ.

But this effect can be achieved with a separate vacuum pump too.